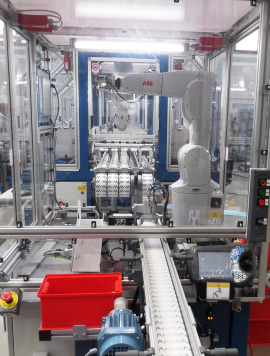

Denken Italia realized the modular system test cells, it’s allows to implement the sorting line, increasing the production potential. The transport of the products is carried out on polyvertebrated chain managed by the first sorting station with the use of an anthropomorphic robot.

The main line consists of 4 individual cells where an anthropomorphic robot picks up and deposits the products on test stations. The electrowelded tubular of the cell structure allows to use the robot in position hanging, reducing the overall dimensions in the work area.

A collection system of production and traceability data manages the entire line, interfacing single test station with the company database from which the production orders are sent. Denken Italia combine men and ideas, skills and technology, at the service of the development of automated systems for assembly, monitoring, measurement and control, with the aim to improve the quality, efficiency and sustainability of products and production processes.

Visit our production departments or contact us to take an apponitment with our technicians for a careful evaluation and an appropriate proposal to meet your needs.

It is nice to know that automation is a great way to increase efficiency. This a wonderful way to make sure that you are getting the most from your machines. My friend looking into gold mining machines would love knowing this.